We partner with state owned enterprises to support key players in major economic sectors and to simulate manufacturing and support SMMEs in their value chain. We also play a scientific and technical advisory role in key sectors such as energy, as well as in transport and logistics.

Mapping South Africa’s Transport Challenges

South Africa faces a myriad of transport-related challenges such as road and rail infrastructure maintenance backlogs, the poor condition of road and rail public transport vehicles, poor public transport services and inadequate public transport in rural areas, all of which adversely affect other sectors and the country’s economic development. To help address these challenges, the CSIR is conducting a detailed analysis of the entire transport sector and is creating a comprehensive model of transport interactions between economic sectors. With Transnet being a key player in the country’s transport sector, the CSIR is also designing various specific, practical interventions that will assist Transnet in its operations.

The Transnet/CSIR partnership entails a joint research and development centre. Though this partnership, efficiency in logistics will be improved, thus lowering the cost of doing business in South Africa and the manufacturing of locomotives/components will stimulate South Africa’s manufacturing industry.

Research and Development Projects To Help Optimise Transnet Operations

Having entered into a partnership with Transnet, the CSIR is involved in a range of projects to help the entity optimise its operations across the transport sector. These projects include the development of a new locally designed locomotive control system, refining laser refurbishment and the manufacturing processes for locomotive and wagon components, creating a streamlined business model for Transnet’s operations on the African continent and developing modelling and simulation software that will enhance Transnet’s wagon production line. In months to come, numerous additional Transnet partner projects will be announced.

Supporting Eskom

Over the past year, the CSIR, in partnership with Eskom, has made significant strides in the refurbishment of high-value steam turbine components, including turbine rotor shafts and turbine blades. Previously, turbine rotors were repaired by the original equipment manufacturers. This was expensive and time-consuming as it implied shipping large, heavy components to Europe. A local repair capability will save costs and time and in the event of unscheduled maintenance, it would significantly reduce the downtime of the power station.

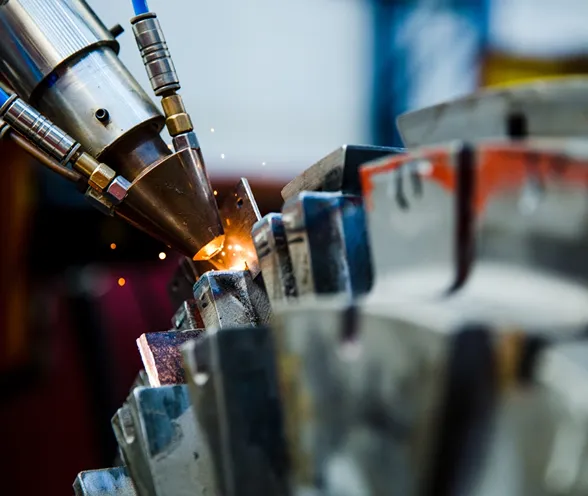

The CSIR developed a laser cladding process for the refurbishment of steam turbine rotor journals. Until now, damaged turbine blades were scrapped in spite of their high value because no repair process was available for these components, which are critical to safety.

Occasionally, brand new blades had to also be scrapped. This is an inevitable consequence of the way in which certain types of blades are mounted on the rotor. In this case, the tips of the blades are connected by a circular band, known as a shroud. The shroud is fastened to the blade tips by means of protrusions, called tenons, on the end of the tips that fit through holes in the shroud. After the shroud has been fitted over the tenons, the ends of the tenons are peened to keep the shroud in place in a manner similar to a rivet. If any one of the blades that are connected by the shroud has to be removed, for whatever reason, the entire shroud has to be replaced. This implies that all the tenons on all the blades have to be machined off after which none of these blades can be reused, regardless of its condition.

The CSIR and Eskom developed a laser additive manufacturing process to reconstruct the tenons. Near net-shaped tenons are produced on the blade tip after which they are machined to final dimensions. The success of this development was made possible by the ability of the process to deliver the material integrity that is essential for this application.