What we do

Contact information:

Highlights

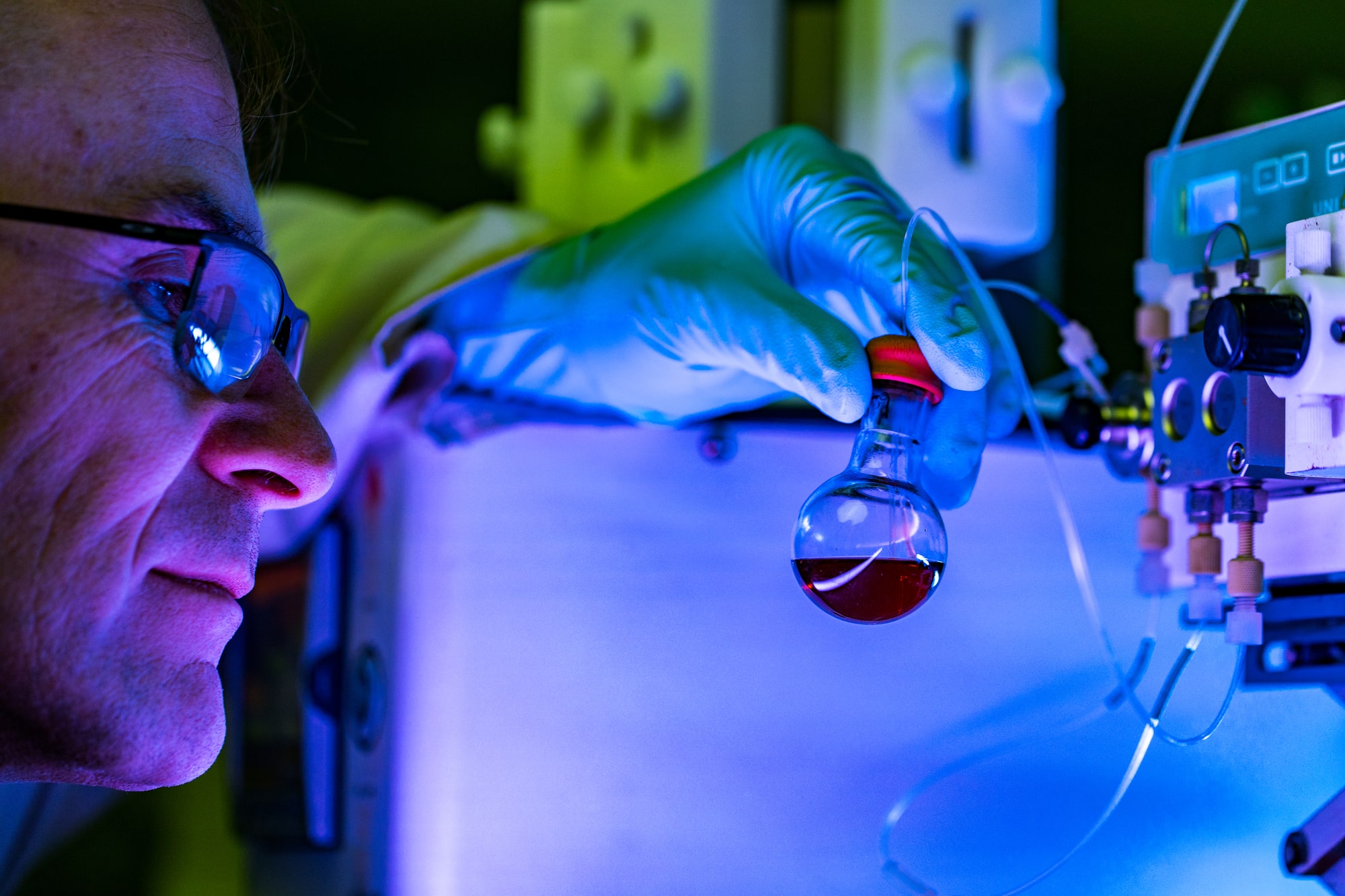

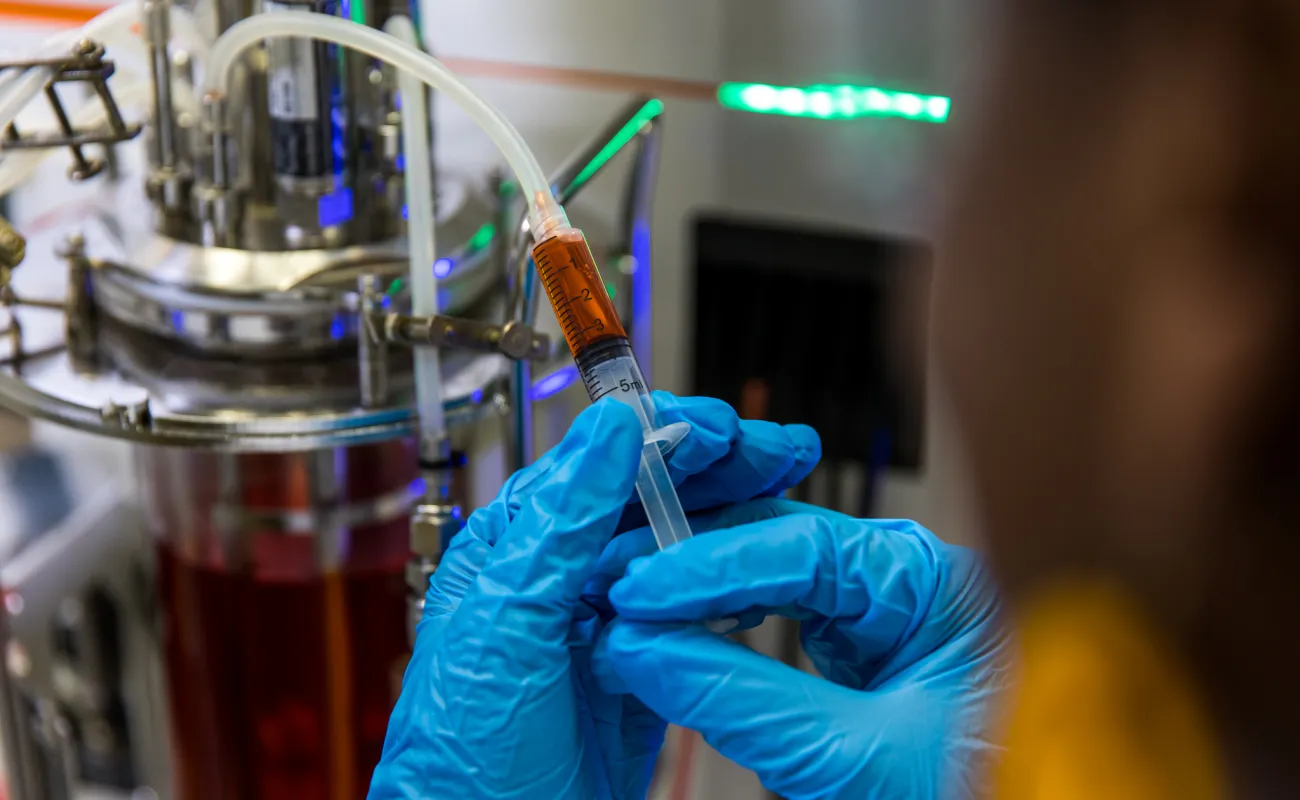

Green technologies to recover high-value products from citrus waste

The CSIR has developed a technology that uses a cheaper compound found in orange oil, which is then bioconverted with an enzyme system to nootkatone at significant yields. The collaboration between the CSIR and APBIO resulted from the Industrial Biocatalysis Hub’s mission to develop and localise technologies using biocatalysis, in line with a more circular agricultural approach to reduce waste. Read more or watch.

An optimised process for local production of orris butter for fragrance industry

The CSIR assisted small business Puris (Pty) Ltd in developing a process to accelerate orris butter production. Orris butter, an essential oil with a powdery aroma derived from iris bulbs, is used in the flavour and fragrance industry, but is not currently produced locally. The CSIR’s green method uses fresh orris root, in contrast to the current methods that involve either maturing the orris root for two to five years or extracting the iridals by boiling in alcohol for extended periods. The CSIR approach offers increased production yields, higher concentrations of the required irones and the use of cost-effective green chemicals.

A green, safe process to produce pharmaceutical precursor

The CSIR has assisted Linuset, a small, medium and micro enterprise, to develop a greener and safer process for the commercial production of racemic phenibut as a precursor for a broad range of pharmaceuticals. Globally, it is used to treat, among others, anxiety and insomnia. Racemic phenibut is best known globally for its use as a central nervous system depressant, enhancing the effects of sleeping pills, narcotics, antipsychotic and antiparkinsonian drugs. Linuset will produce racemic phenibut as an intermediate in the production of other drugs to meet the growing demand in the United States of America.

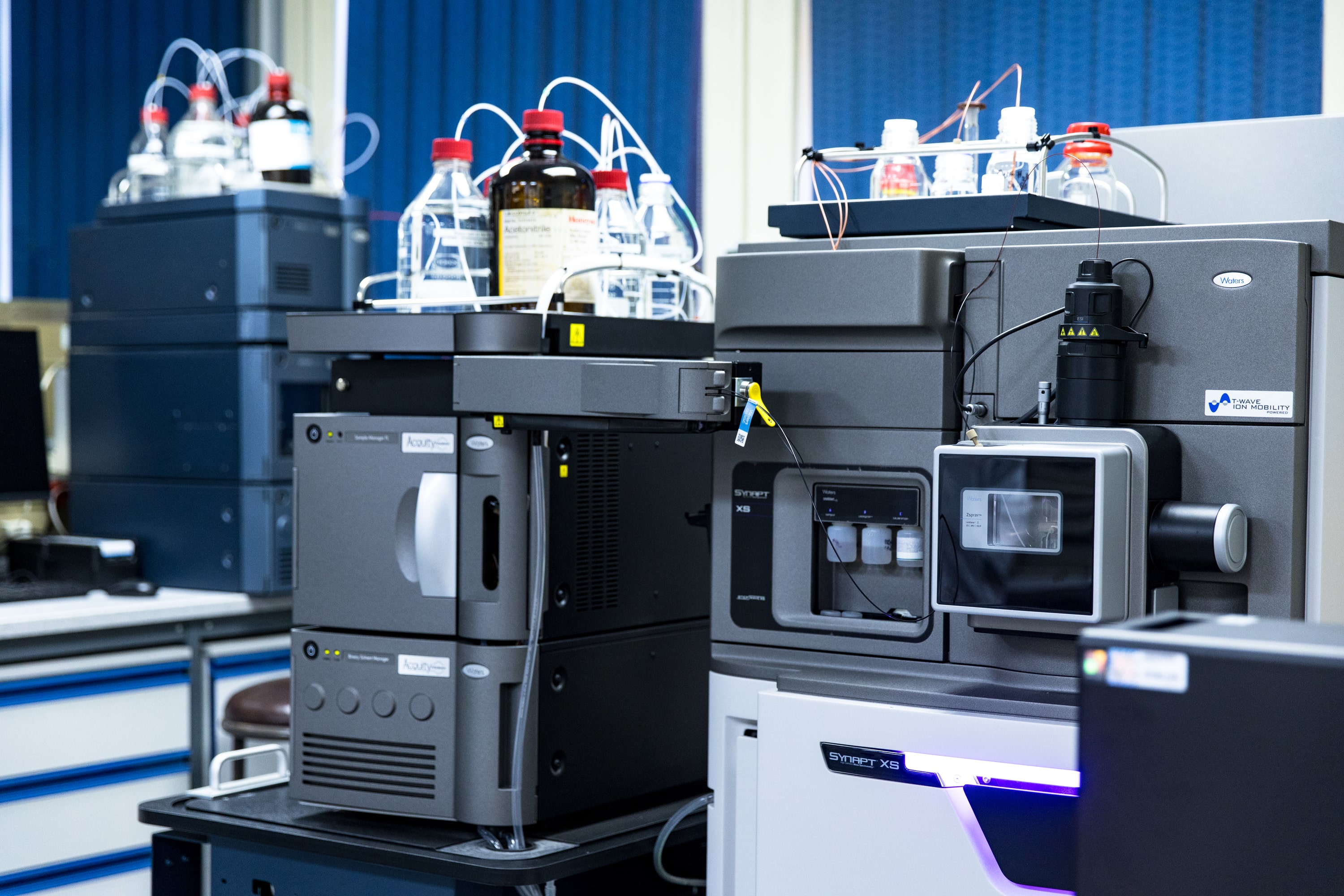

New mass spectrometry instrument for interrogation of complex samples

The CSIR and the University of Johannesburg’s Research Centre for Plant Metabolomics have acquired a Synapt XS mass spectrometer, enabling scientists to interrogate complex biological mixtures. The acquisition was made possible through joint funding from the two institutions. Research fields such as biocatalysis, pharmaceuticals, veterinary pharmaceuticals, plant metabolites, as well as flavours and fragrances, require the analysis and investigation of extremely complex samples. Advanced mass spectrometry instruments are highly sensitive and can provide accurate fragmentation data.

Our capabilities

The Industrial Biocatalysis Hub provides a platform for industrial assimilation of biocatalysis technology through human capital development, applied research and development and technology transfer, and for participation with industry. It integrates and expands its networks into a common biocatalysis value chain within the South African economy from idea generation to commercialisation.

Our facilities