What we do

Contact information:

Highlights

South Africa’s biorefinery journey: From innovation to industrial impact

Imagine transforming forestry waste and agricultural by-products, such as sawdust and sugarcane residues, into high-value green chemicals, advanced materials, sustainable fuels and green energy. That is the promise of biorefineries: converting biological resources into a spectrum of market-ready products, much like petroleum refineries do with crude oil, but using renewable biomass as feedstock. Read more.

Better, greener plastic products from waste streams

The CSIR has formulated a new biocomposite material using waste sawdust and recycled plastics as an alternative to fossil-based material for Plastech SA. This innovation adds value to two waste streams: sawdust, a byproduct of the sawmilling industry and recycled polypropylene. Using melt extrusion techniques, researchers produced biocomposite pellets suitable for injection moulding and the manufacture of low-cost building materials with a reduced carbon footprint and improved performance.

Maximising the value of underutilised byproducts for a circular economy

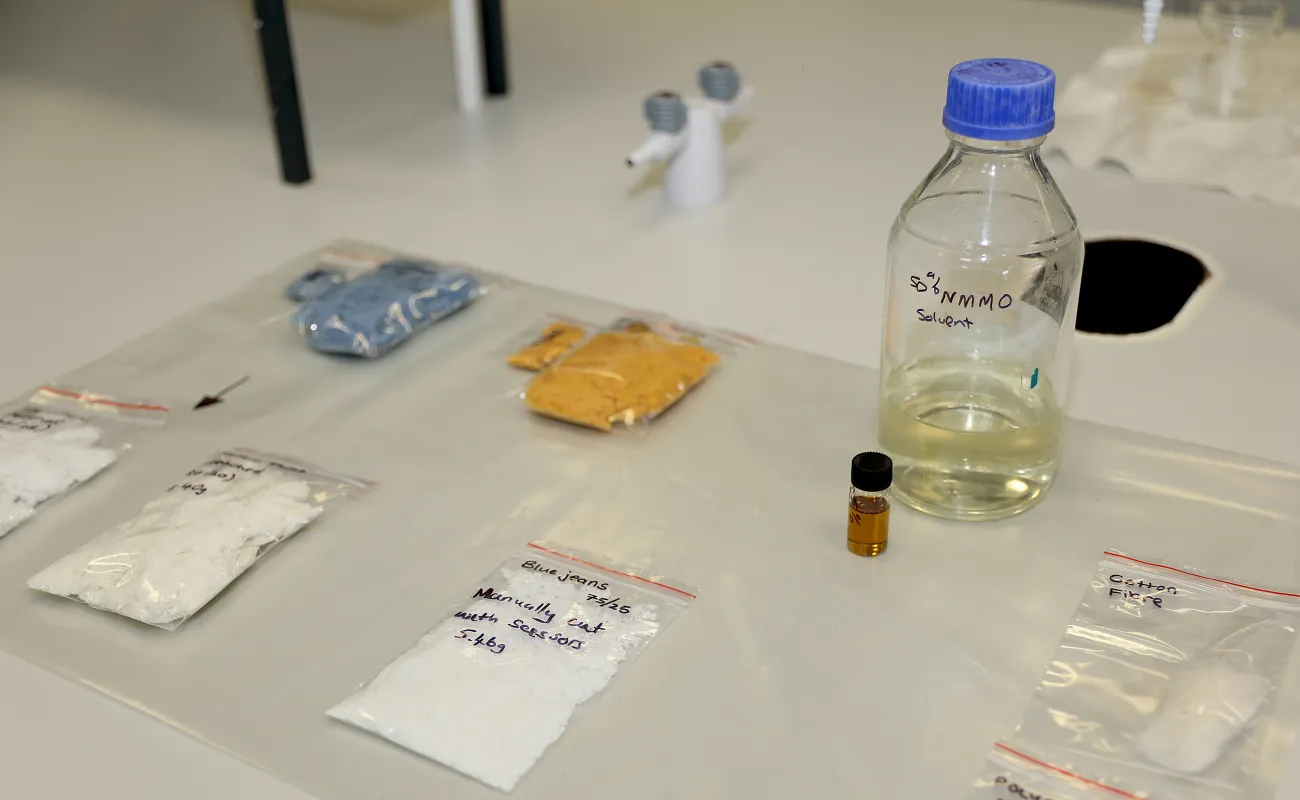

The CSIR Biorefinery Industry Development Facility assists local industry to improve its competitiveness by providing access to specialised analytical and pilot-scale facilities to ensure a more sustainable way of using the country’s biomass resources. Watch.

Recovering useful fibres from used potato bags

The CSIR has developed a technology to recover fibres from used potato bags. Fibres recovered from used potato bags are repurposed to manufacture paper-based packaging materials such as fluting, a corrugated medium used in paper packaging. The use of waste paper offers economic and environmental benefits in line with circular economy ideals. This innovation is co-funded by the Department of Science, Technology and Innovation and the Paper Manufacturers Association of South Africa.

Read more.

Unlocking high-value products from sawdust biomass waste

The CSIR is developing a protocol aimed at optimising the extraction of xylitol, a high-value product from xylose, a sugar isolated from wood or sawdust biomass. Maximising the value of underutilised byproducts or waste aligns closely with the principles of a circular economy. The new extraction protocol provides comprehensive guidelines for evaluating and processing parameters to convert xylose into an important platform for sustainable bioproducts, particularly targeting the xylitol market.

Our facilities