What we do

Contact information:

Highlights

A biodegradable rapid test to detect E. Coli in water

The CSIR has developed a biodegradable single-use kit that can detect E. coli in water within six hours. This innovative solution is faster than existing lateral flow detection devices, easy for non-experts to use and circumvents the need for lengthy laboratory testing. The CSIR-developed device incorporates systems that filter water, incubates the bacteria and multiplies it to a detectable level. All these elements are integrated into a single, biodegradable unit.

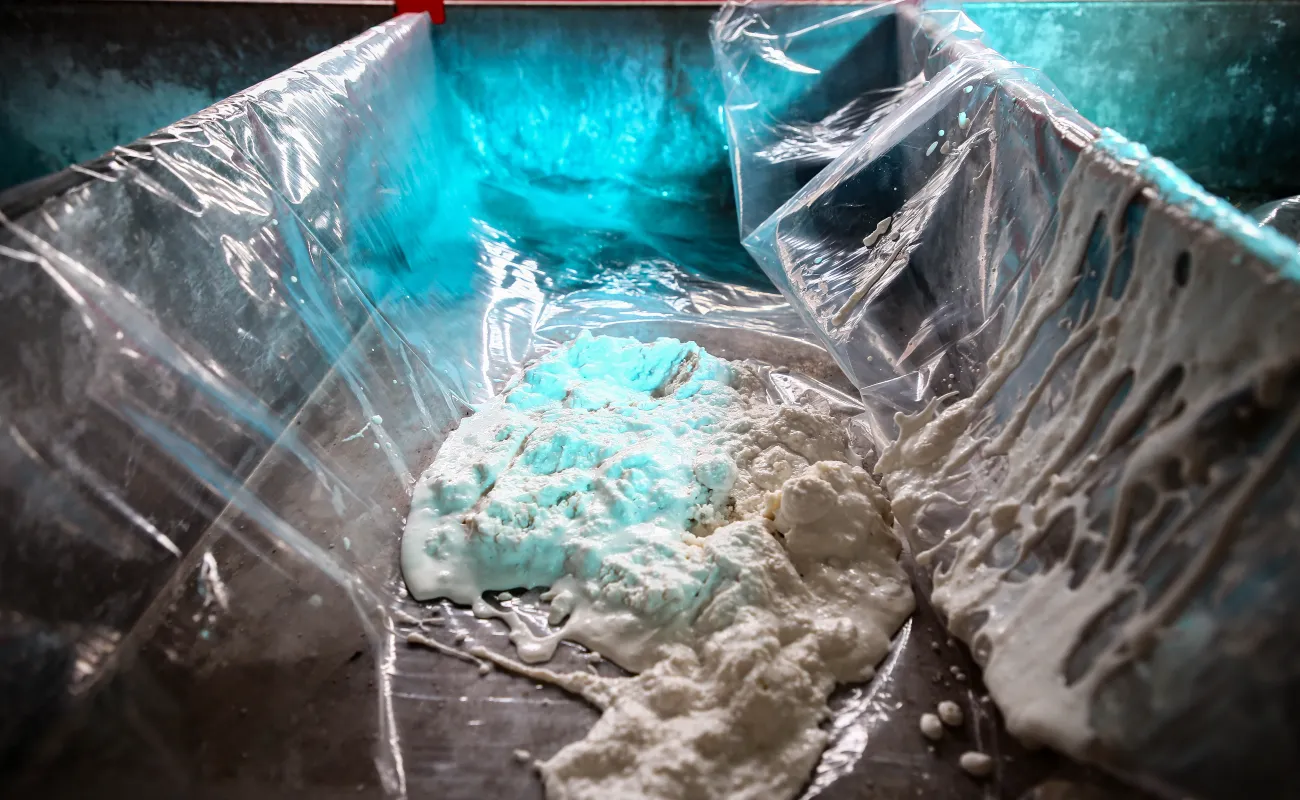

CSIR develops compostable food packaging solution

CSIR researchers have developed biodegradable food packaging that effectively blocks oxygen, helping to prevent spoilage and extend shelf life. This packaging presents a sustainable alternative to conventional plastics, which contribute to environmental pollution. Designed to retain its shape and integrity even at high temperatures, it is particularly suitable for ready-to-eat products – items often not recycled due to food contamination. Read more.

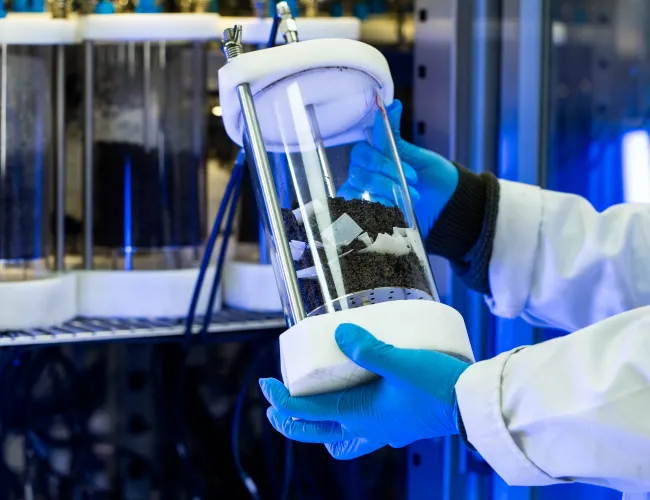

Scientists close to 86% reduction in hydrogen cylinder storage pressure

CSIR researchers are at an advanced stage of developing a technology that compacts one kilogram of hydrogen into a 20-litre cylinder at just 100 bars – 86% lower pressure than current compression technology allows for. This technology will enable hydrogen-powered vehicles to store fuel at reduced pressures, enhancing safety and affordability. Read more.

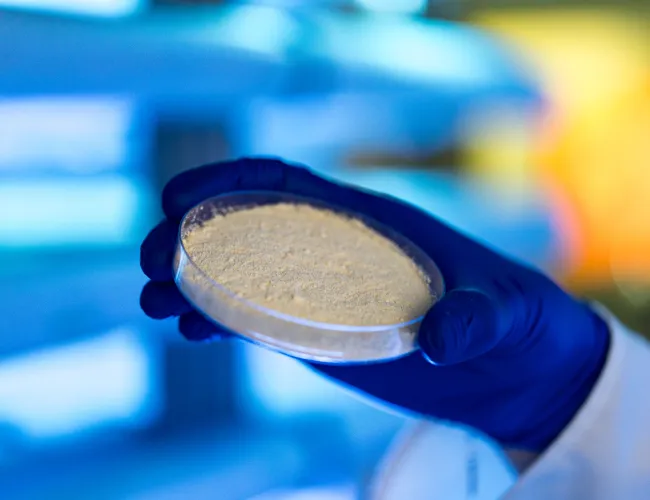

Can we turn prawn shells into firefighter gear?

Within the next three years, CSIR researchers aim to close the recycling loop on chitinous waste by transforming scraps from lobster, prawns and other shellfish into eco-friendly products. They are developing chemical processes to extract chitin from shellfish waste and exploring ways to incorporate chitosan into useful products. Chitin can be converted into chitosan, a polymer that can be woven into other common synthetic polymers used in products such as fabrics or polyvinyl chloride pipes. Read more.

Our facilities