What we do

Contact information:

Highlights

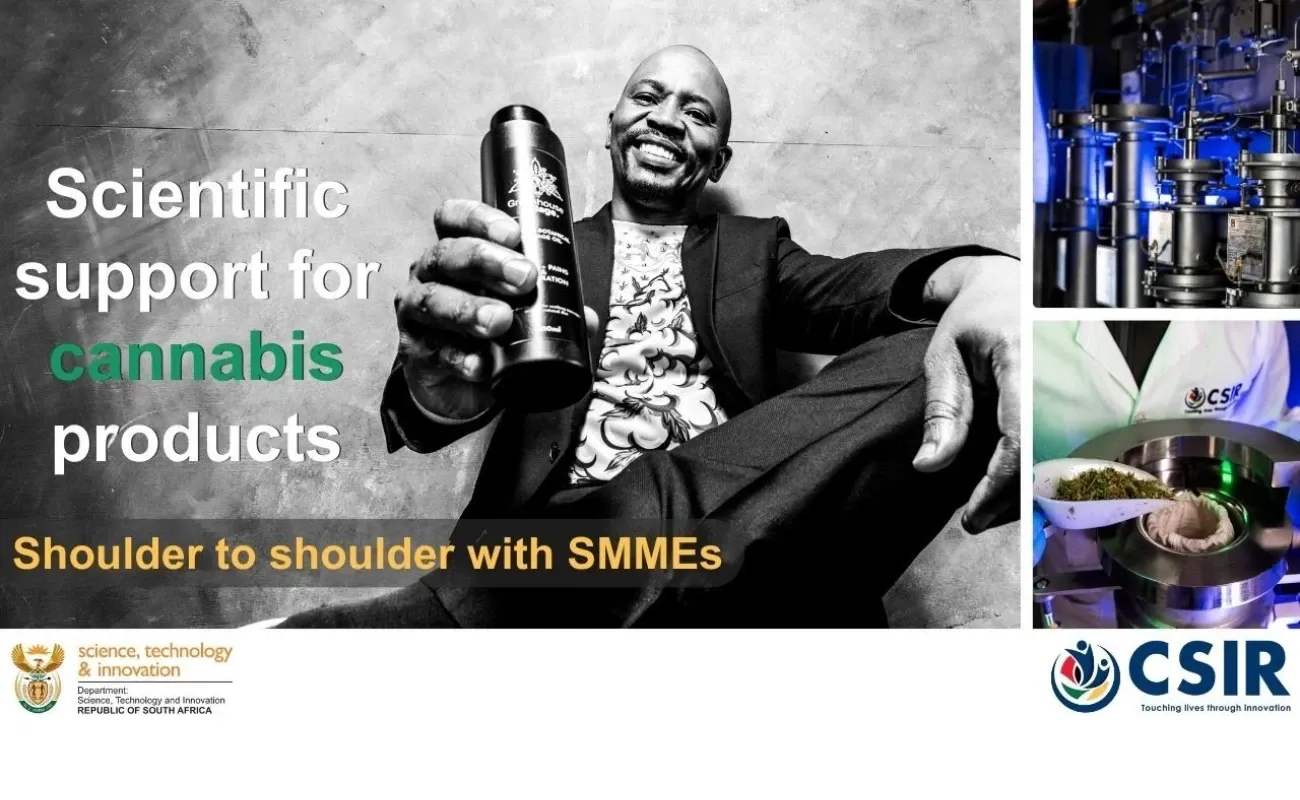

Scientific support for South African cannabis products

Local cannabis cosmetic business Green House Village is one of 23 small, medium and micro enterprises that the CSIR has supported to date in developing high-quality, regulatory-compliant, safe, effective and affordable cannabis products for local and international markets. Watch. The CSIR’s agroprocessing facilities are equipped with supercritical carbon dioxide extraction equipment for cannabis processing, while prototype development takes place in its laboratories. To date, over 40 cannabidiol-infused and cannabis-based prototypes have been developed, including nutraceuticals, cosmeceuticals and herbal remedies.

Aloe ferox harvesting, processing and trading hub

A United Nations Development Programme project, implemented by the Department of Forestry, Fisheries and the Environment and the CSIR, aims to develop an aloe ferox harvesting, processing and trading hub in the Eastern Cape. The hub will promote sustainable and equitable benefit sharing across the value chain. Read more.

Capabilities

We specialise in the formulation, development and small-scale production of high-quality plant-based capsule products. Our capabilities support research and innovation in the nutraceutical, pharmaceutical and botanical supplement sectors through controlled, precise and efficient capsule manufacturing.

Our facilities

Resources