What we do

Contact information:

Highlights

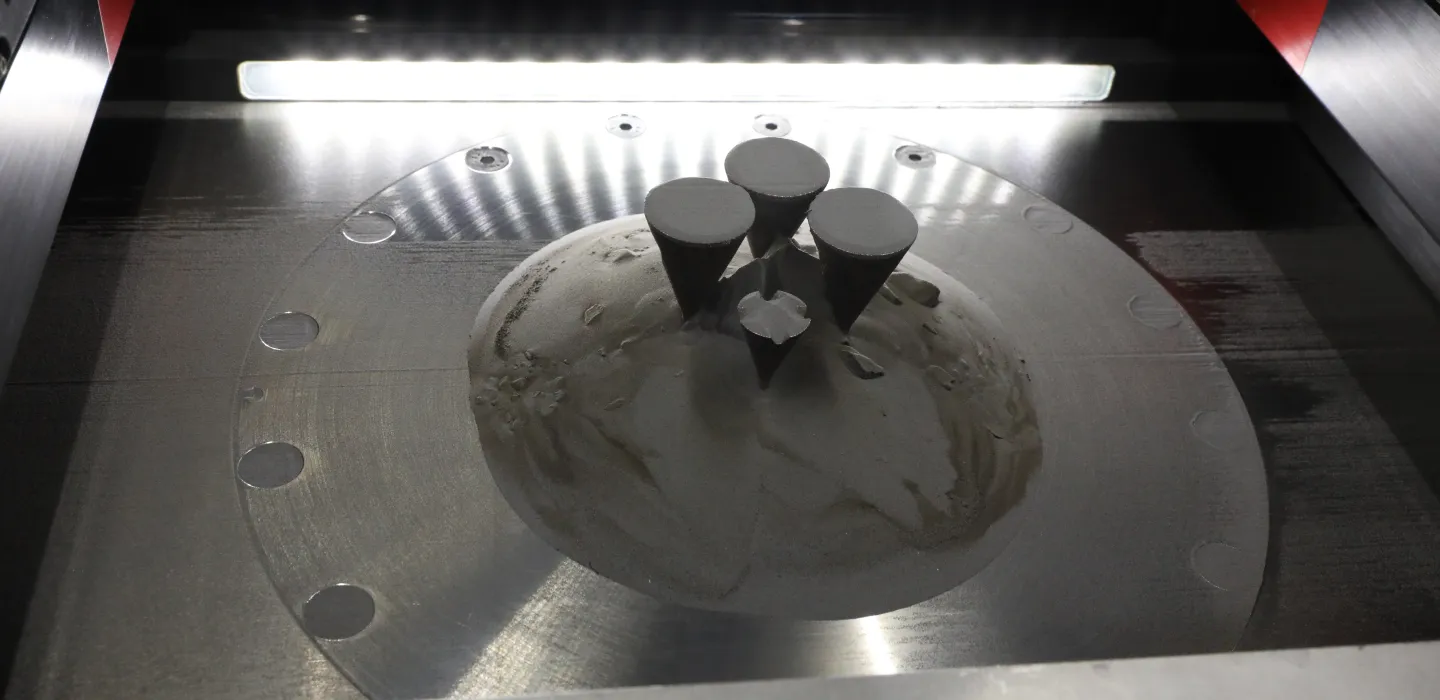

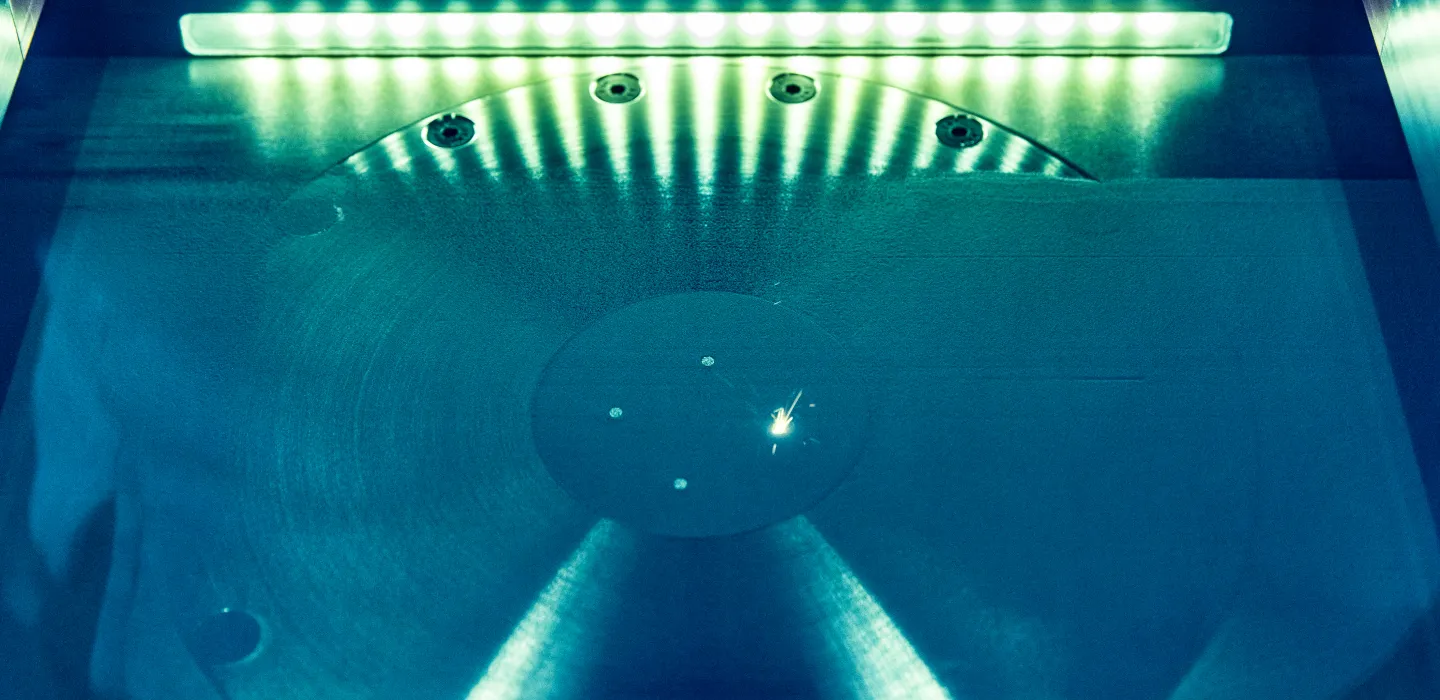

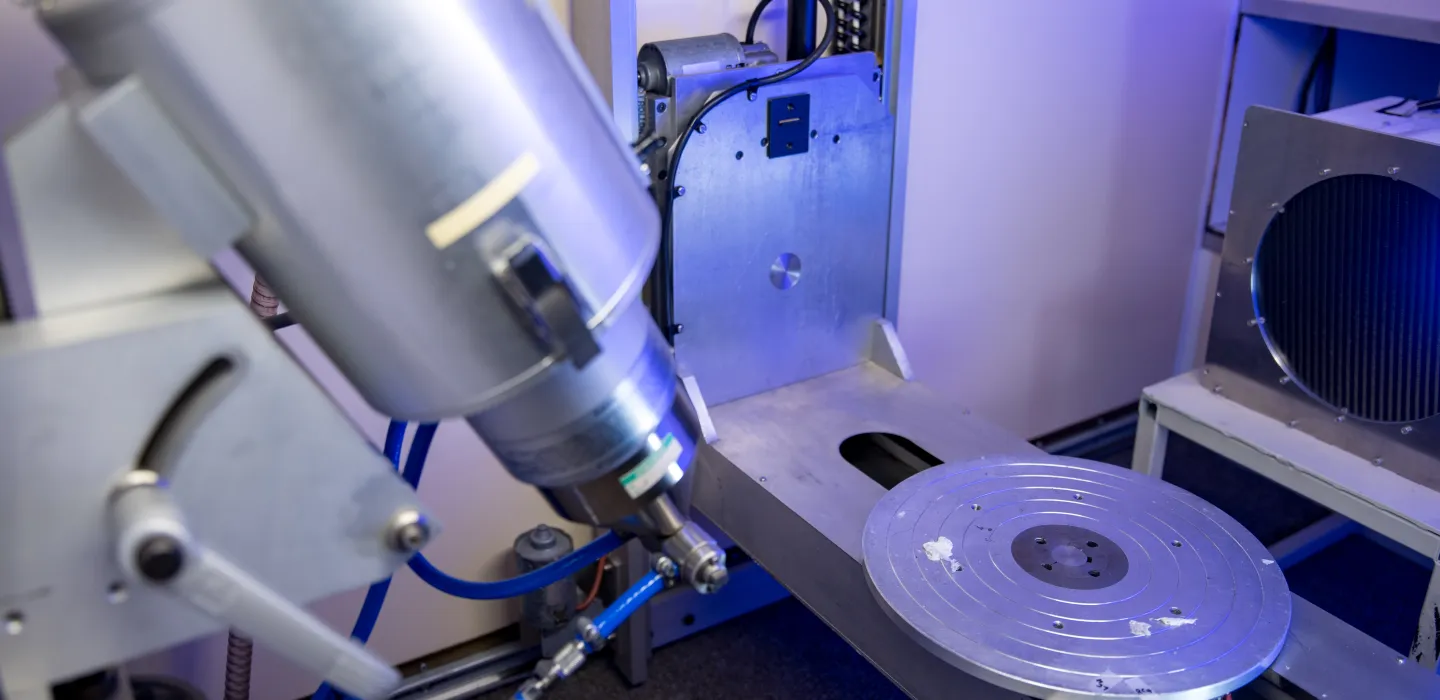

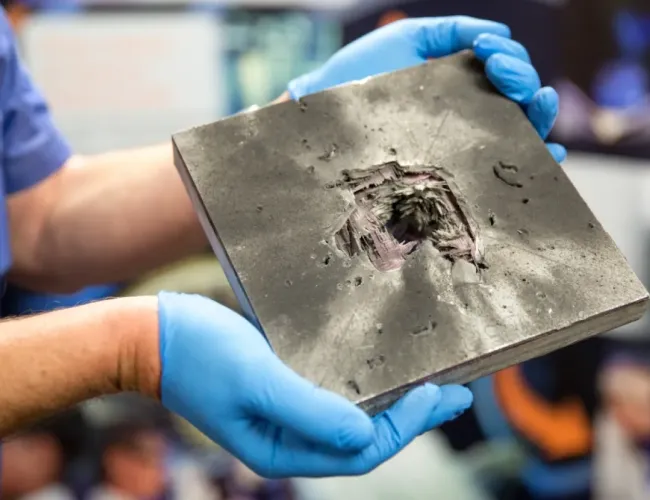

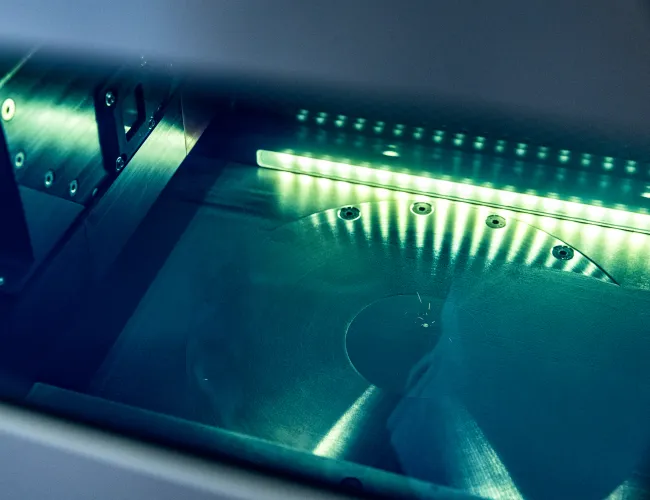

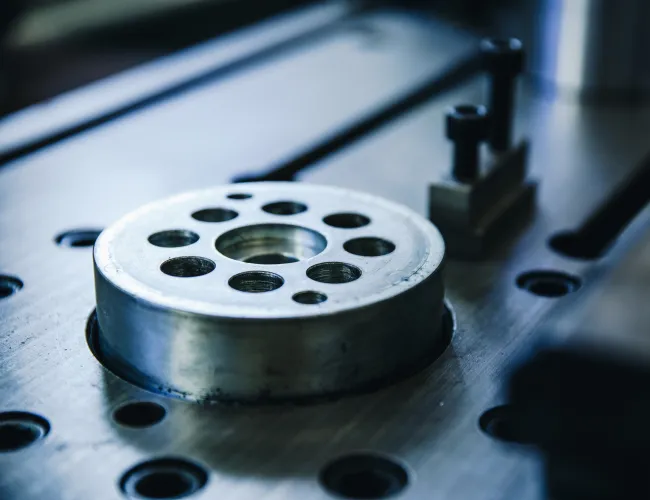

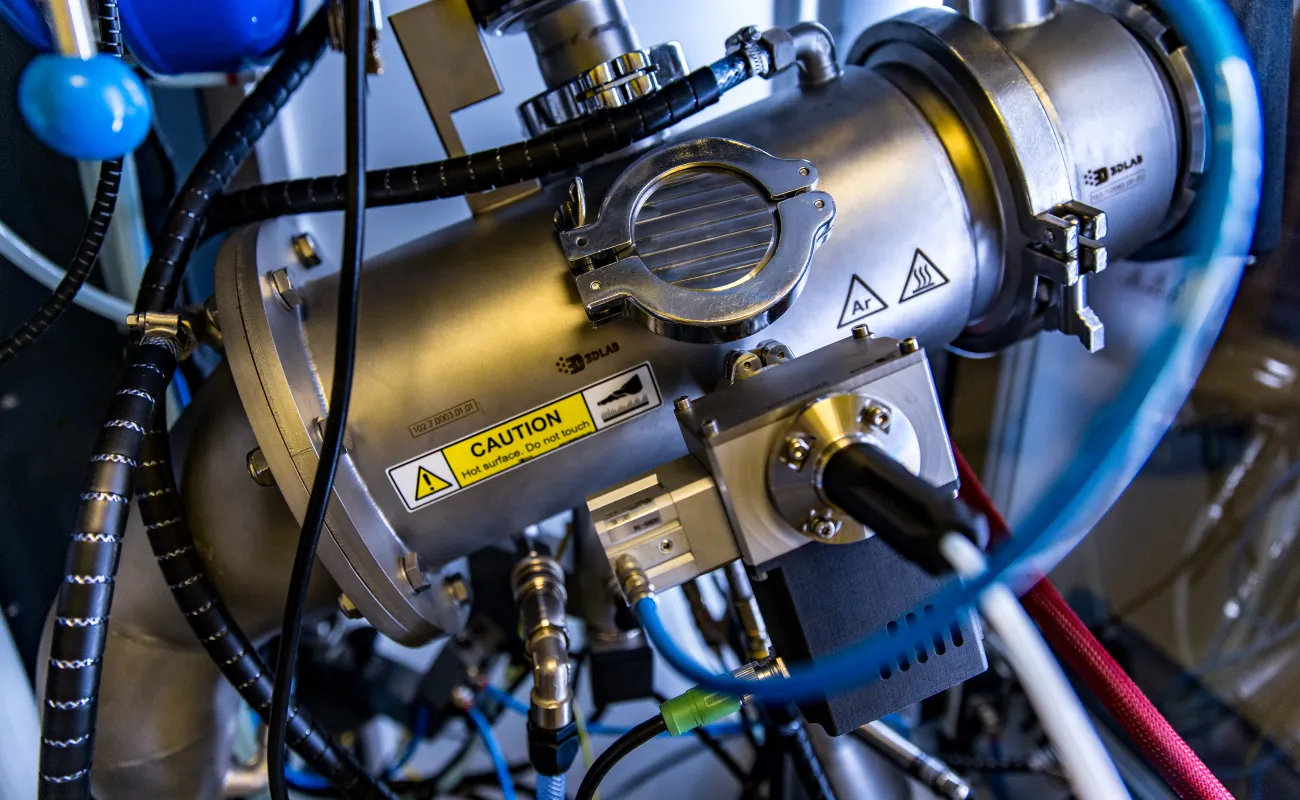

First batch of stainless-steel powder atomised

The CSIR’s new ultrasonic atomiser facility has produced its first batch of 316L stainless steel powder – a high-quality material used in three-dimensional (3D) printing. Approximately 8 kg of powder was produced during this initial run. In additive manufacturing, 3D printing can be achieved through a technique called powder bed fusion, where an object is constructed layer by layer using a heat source to fuse powder particles together. South African businesses have traditionally relied on imported high-quality powders for this process. The ultrasonic atomiser machine was co-funded by the National Research Foundation, an entity of the Department of Science, Technology and Innovation.

Our research

Our facilities