Laser-based services

Our services are rooted in decades of research and development. We offer a range of expert laser engineering services, including laser welding, shock peening, or cladding with the aim of refurbishing components, as well as performance enhancement or extending the useful life by improving resilience and hardness.

Contact information:

Highlights

Our capabilities

Laser-based refurbishment and performance enhancement includes technologies and techniques outlined below.

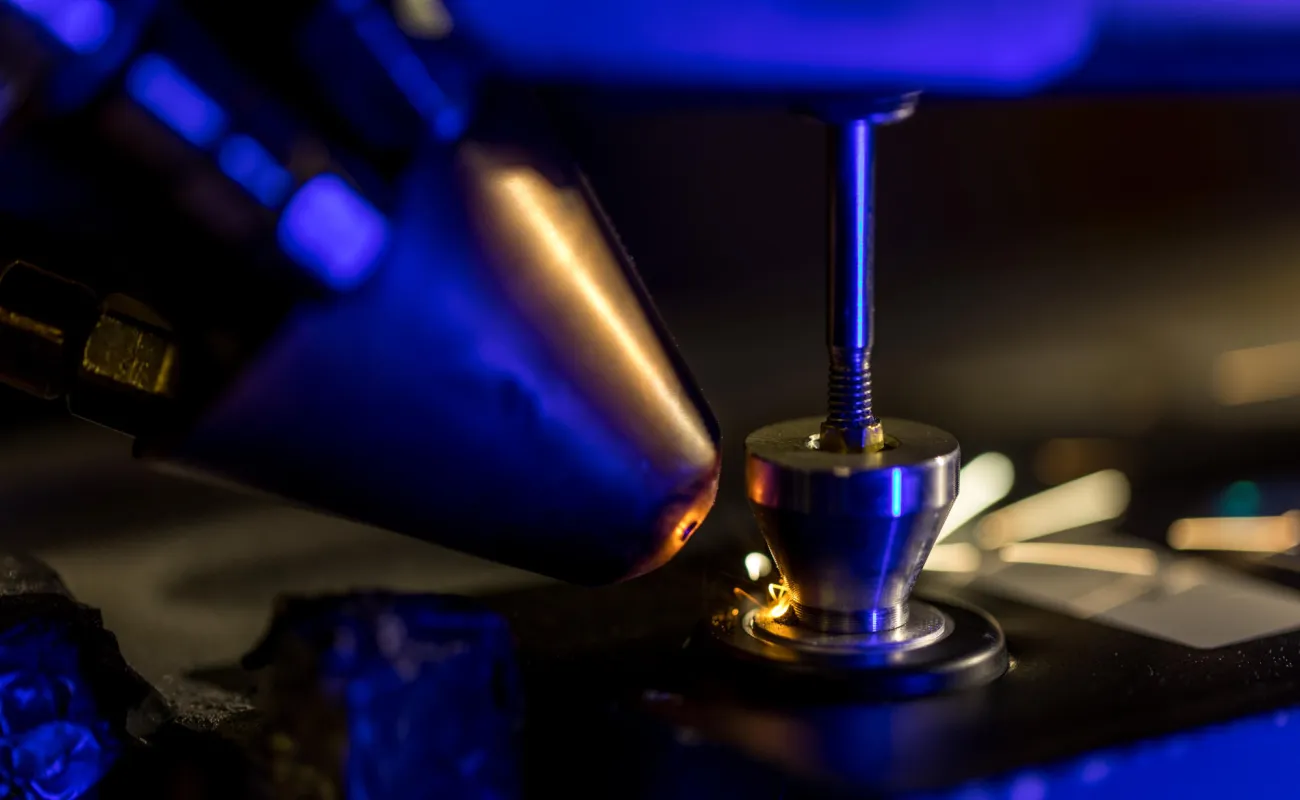

Laser cladding or laser weld overlay

Laser cladding or laser weld overlay is typically used by original equipment manufacturers and service providers to power generation, rail or defence companies. Working mainly on existing, high-value components, our team have mobile laser systems to work on large parts at the client’s workshops.

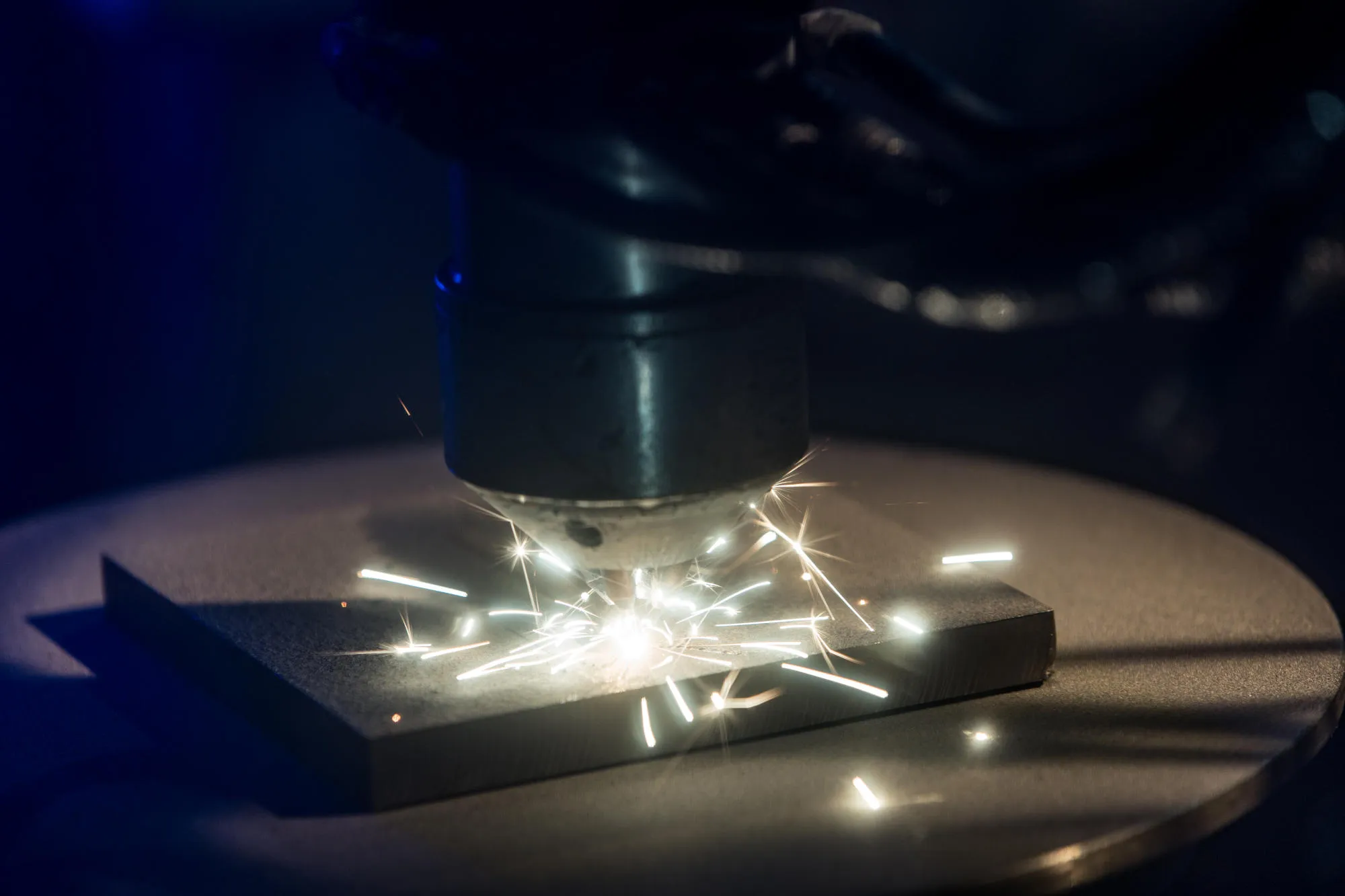

Laser hardening

Laser hardening of high-value parts finds application mostly in defence, mining and the yellow goods industries.

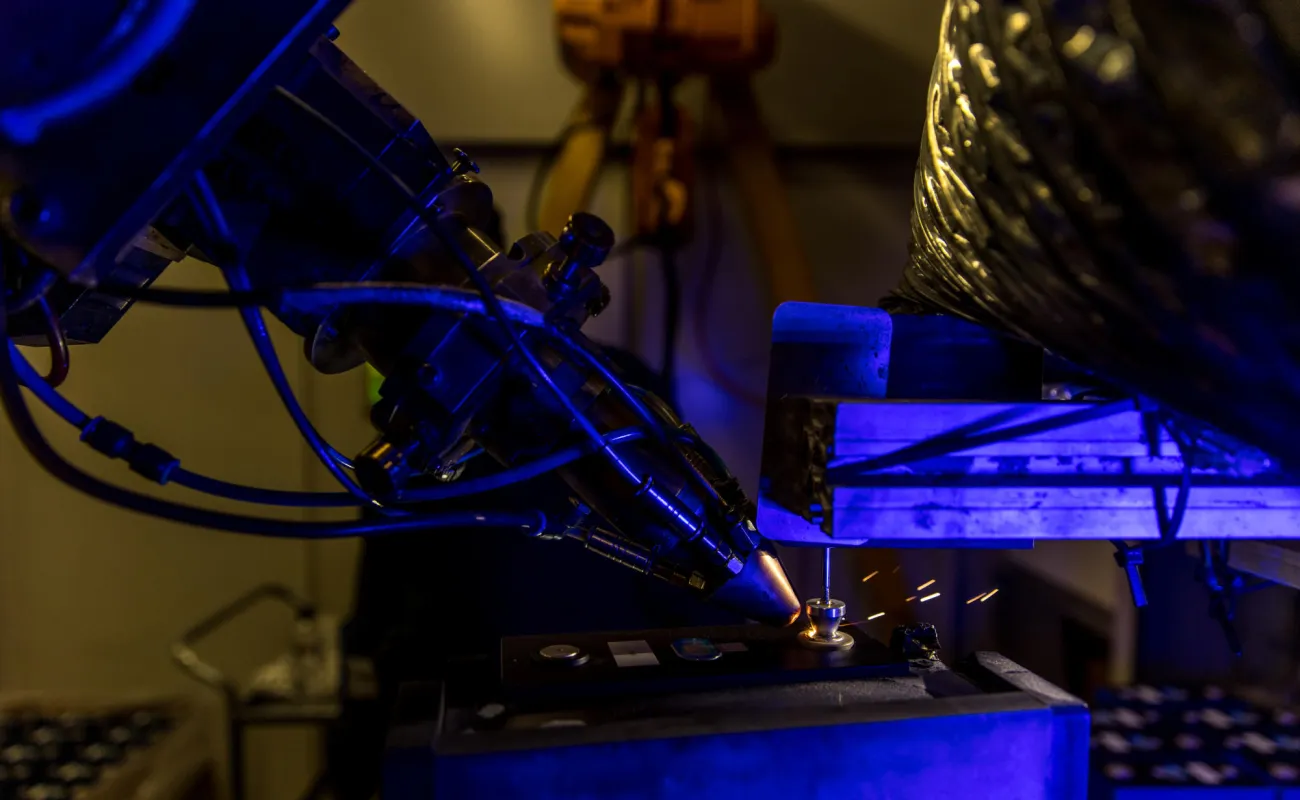

Laser welding

Laser welding entails joining parts or components using laser technology as part of the parts fabrication process. It is a very specialised, custom service for specific products that we have performed in the food industry on food-grade stainless materials for stirrers, in the renewable energy industry for the welding of battery terminals, and for the nuclear industry on the welding of isotope targets.

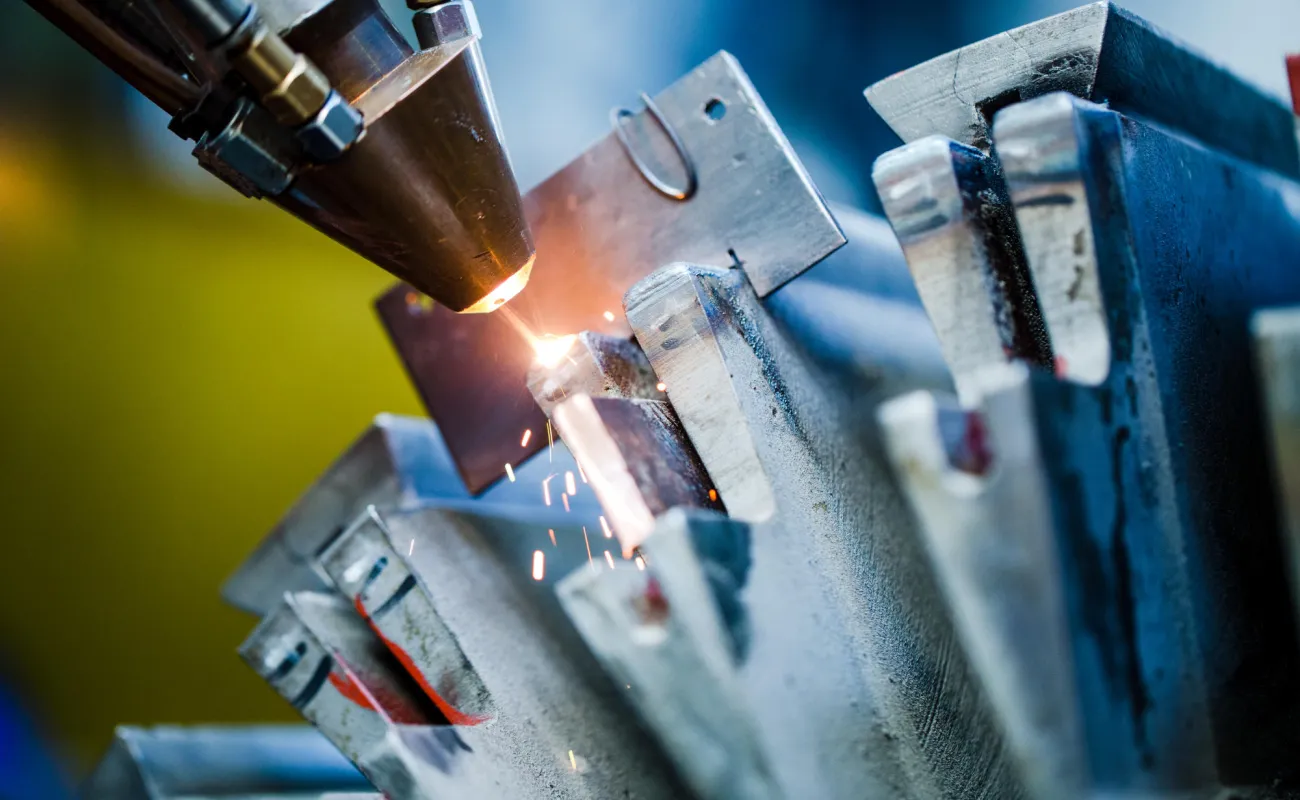

Laser cutting (2D and 3D cutting)

Widely used in industry, 3D cutting is popular in the automotive and rail industries for rimming and cutting of body panels after the forming process of sheets into body parts.