Metal additive manufacturing

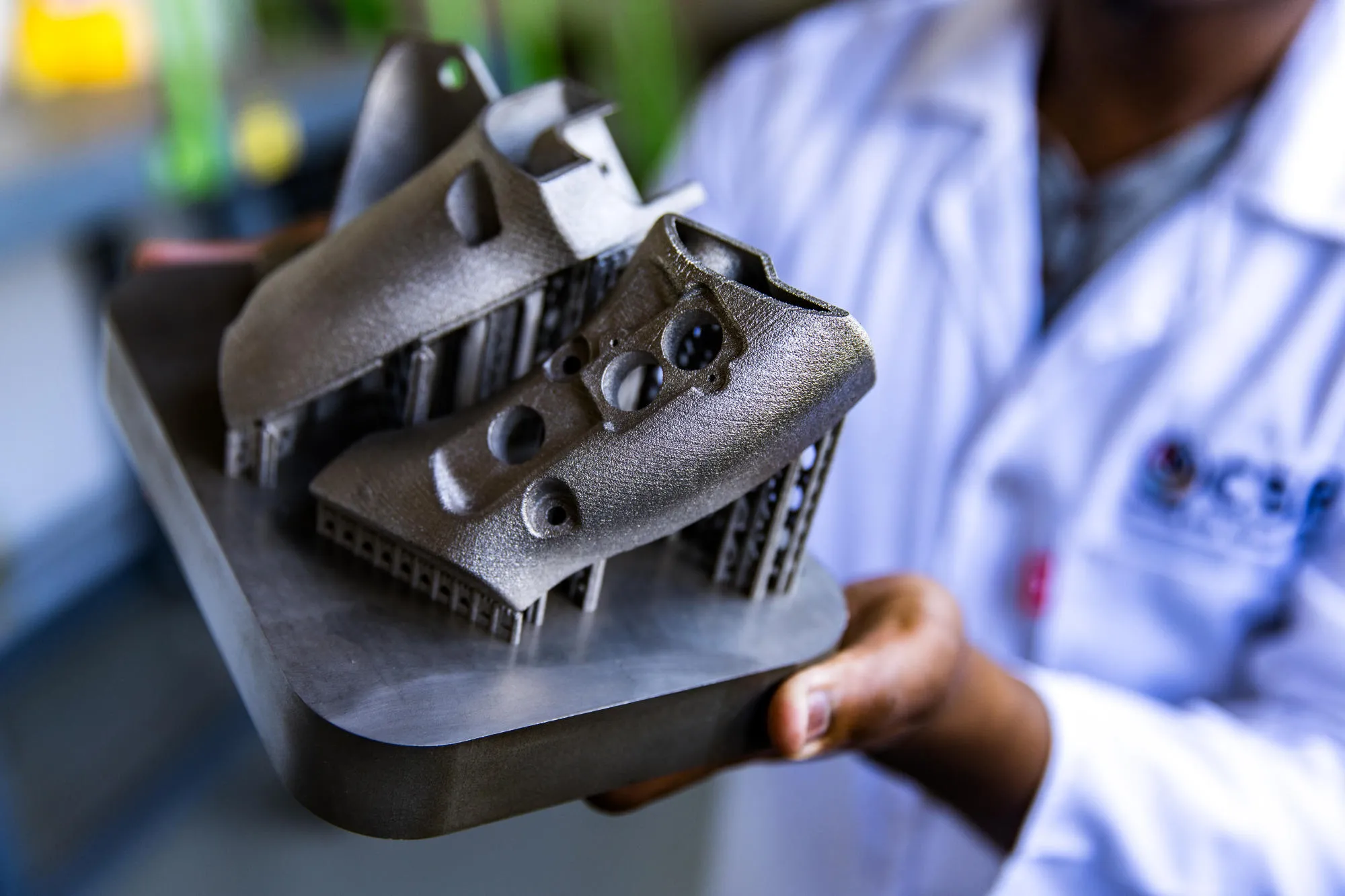

A major benefit of additive manufacturing is the ability to produce highly complex shapes and geometric features. Typically, any part that can be generated in three-dimensional (3D) format in a computer model can be printed layer by layer. This flexibility, combined with limited raw material wastage, makes this an attractive manufacturing option. Our work is not just printing; we undertake research into different materials and develop printers to support a strong local additive manufacturing capability.

Contact information:

Highlights

Our capabilities

Laser based powder-bed fusion

Powder bed fusion is not a new technology; it was originally used for prototyping in the thermoplastics industry. When used with a laser on high value metals such as titanium, stainless steels, aluminium, nickel- or cobalt/chromium-alloys, the technology offers significant advantages compared to machining and other manufacturing methods. For light-weighting, for example, complex lattice structures can be easily manufactured using any of the layering techniques of additive manufacturing.

Our facilities

We produce high-quality parts at high printing speeds using a range of materials including titanium, aluminium, steel and a range of new alloys and polymers not available elsewhere.

Our facilities include custom selective laser sintering machines and can produce large parts up to the size 600 x 600 x 2 000 mm.