Powder metallurgy and testing services

We have a range of metallurgy facilities offering services in additive manufacturing, metal powder atomisation and metal injection moulding, as well as powder metallurgy processing capabilities for various metallic alloys and components. Our focus is on metals and lightweight alloys, providing expert support in product development, rapid prototyping, process development and materials testing.

Contact information:

Highlights

Our capabilities

Press and sinter technology

Press and sinter technology involves compacting metal powders into a desired shape, followed by a sintering process. Sintering increases the strength and integrity of the part as the particles bond under high temperatures. This technology is widely used for producing various industrial components.

Materials development and process development

In materials development and process development, the CSIR focuses on innovating and refining materials to meet specific needs. This includes developing new materials and composites or improving existing ones to enhance their properties, such as durability, strength, and resistance to environmental factors.

Our research

Solution to combat theft of cell phone mast batteries

We are developing high-resistance materials that can be used to prevent the rising theft of cell phone mast batteries. Tests have shown good results in withstanding various forms of physical tampering or attacks. Materials that are resistant to ballistic attack are also being investigated. The research primarily focuses on the development and reinforcement of metal matrix composites, which are known for their strength and durability.

Our facilities

Our facilities are equipped to manufacture high-value components through powder metallurgy processing routes and include a state-of-the-art hot isostatic pressing facility. This is available for post-processing of powder metallurgy products to enhance both properties and performance, also offering powder metallurgy – hot isostatic press as an energy and materials-efficient route for producing near-net-shape products from metal alloy powders.

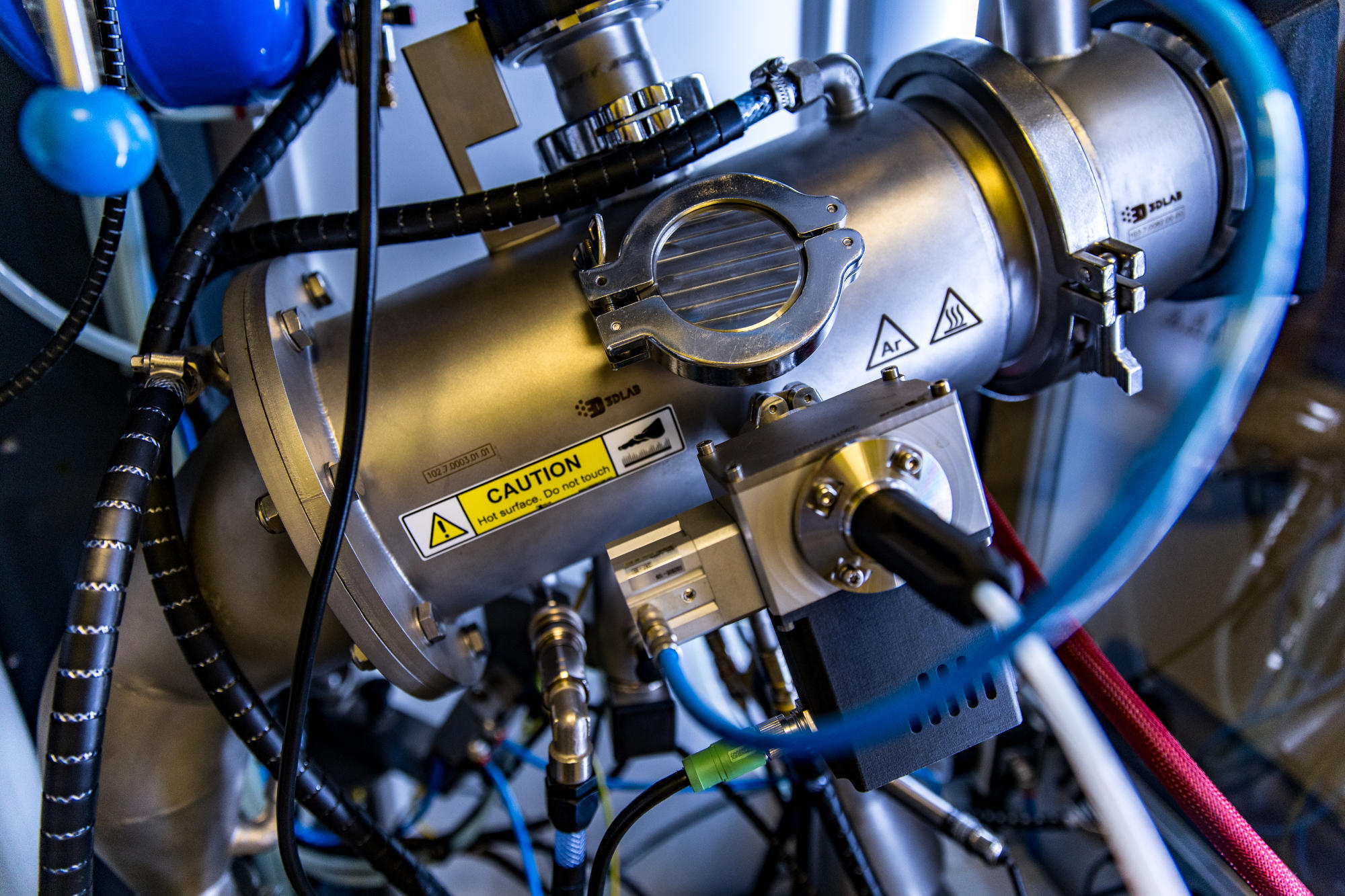

Metal powder atomisation

A new state-of-the-art ultrasonic atomiser facility is used for producing high-quality metal alloy powders as feedstock for a variety of downstream manufacturing processes.

Batches of 316L stainless steel powders have shown excellent properties in terms of density, particle size distribution, and flowability.

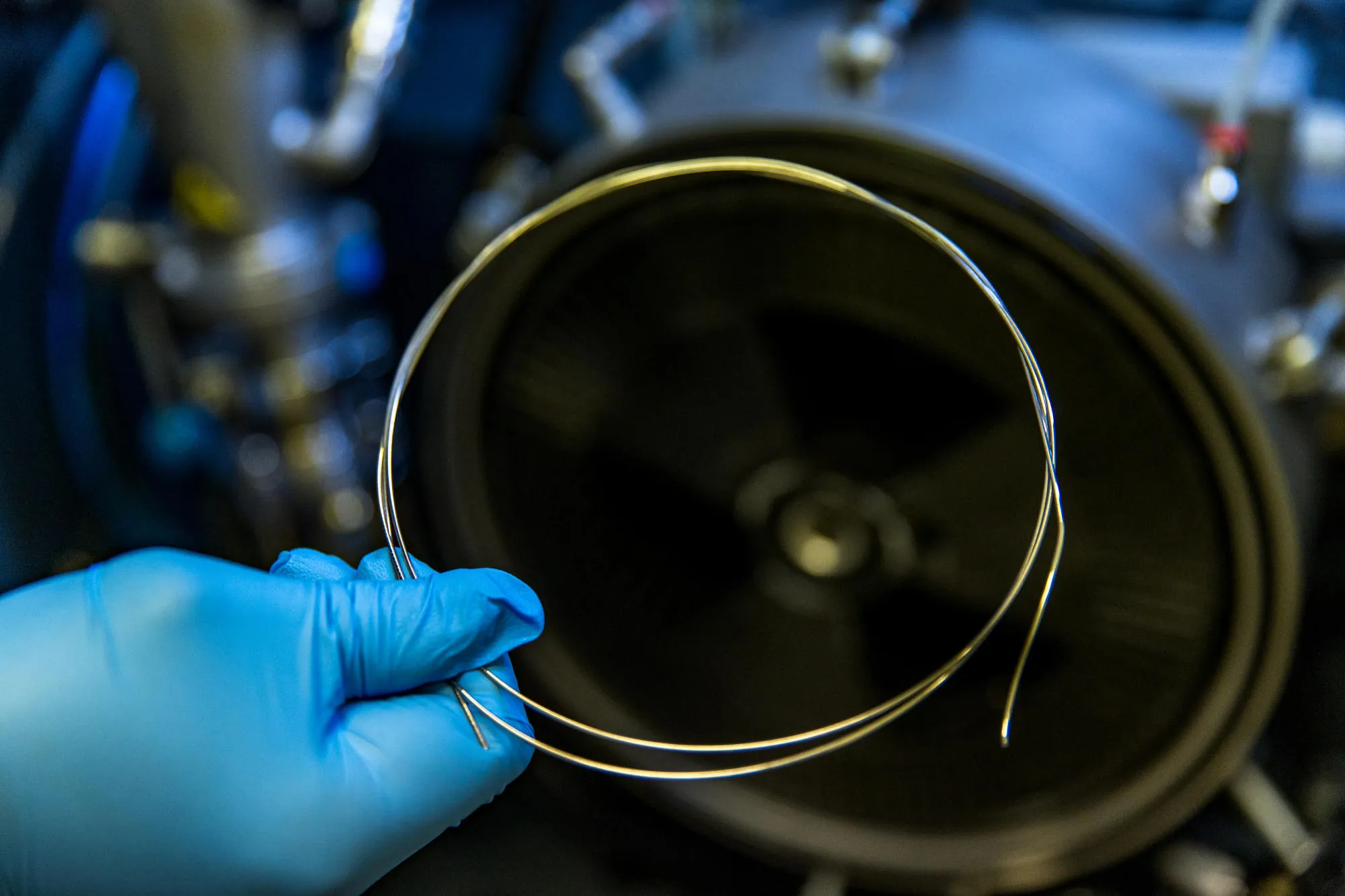

Our current focus is on atomisation of Ti6Al4V powders from metal rods.

Metal powder atomisation is a specialised process for converting molten metal into fine (typically <100 µm) spherical particles using ultrasonic vibrations, which are then cooled and solidified.

Both non-reactive (e.g., iron-based alloys) and reactive (e.g., aluminium, titanium-alloy) powders can be atomised, including high-melting alloys such as refractory metals (Tm > 2 000 °C).

Each powder is subject to stringent quality control and testing to ensure that key properties such as density, particle size distribution, flowability, and purity meet the required standards.

The aim is to localise powder production and replace importation.

Powder characterisation facility

The powder characterisation facility is used to analyse metal powders for their physical and functional properties, as required for various manufacturing processes and industrial applications. It is ISO17025:2017 SANAS T0381 accredited. The facility is equipped to assess particle size, shape, density, surface area and chemical composition. It adds value by providing insights into the flowability and rheology of metal powders – critical factors for additive manufacturing, metal injection moulding and powder metallurgy processes.

Metal injection moulding

The CSIR has established a semi-industrial metal injection moulding (MIM) facility to support local companies in prototyping and low-medium volume production of commercial parts. MIM is used for the cost-effective production of small- to medium-size metal parts of complex geometry with fairly high precision. It is a near-net-shaping process in which metal powders are mixed with a polymeric binder to create a feedstock suitable for injection moulding using typical equipment used for plastics. After the injection moulding step, the binder material is chemically removed from the parts, following which these are sintered at high temperature, resulting in a dense, robust final product with dimensional tolerances within or close to specifications.