The Advanced Design and Manufacturing Innovation Centre

The Advanced Design and Manufacturing Innovation Centre (ADMIC) supports ongoing research into new manufacturing techniques, technologies and materials, as well as specialised design and manufacturing training. It is manufacturing and applied research facility established to support industry, including small, medium and micro enterprises (SMMEs), as well as other local and international industries, including the defence sector. Capabilities range from additive manufacturing using polymer and powder, 3D scanning and product life cycle management.

Unlike many other 3-D printing facilities, ADMIC operates using a precise methodology that takes into consideration the complete product lifecycle - from concept to final product. This centre is dedicated to the complete process, from conceptualising or designing a solution, to material selection, prototyping, testing, manufacturing and delivery.

The centre allows for the design and printing of parts that cannot be manufactured using traditional methods; have a complex design and require the production of integrated components. Printed parts are durable enough to be used as advanced conceptual models, functional prototypes, manufacturing parts and production parts.

Benefits unlocked by the centre:

- Reduced cost of the development of any product.

- Reduced time-to-market of new ideas (including functional products, prototypes and niche solutions).

- Minimised material waste.

- Reduced delivery time frames.

- Improved understanding and knowledge of advanced manufacturing.

- Customised solutions.

Offerings:

- Additive manufacturing, 3D-scanning, advanced design optimisation and product lifecycle management.

Machinery:

Fused-deposition modelling or FDM 900 printer.

Uses a thermoplastic filament, which is heated to its melting point and then extruded, layer by layer, to create a three-dimensional object.

It is ideal for the production of high-accuracy thermoplastic parts used in, for example, approved aircraft and medical grade materials.

Materials range:

- ABS-M30

- ABS-M30i (Bio-compatible)

- ABS-ESD7

- ASA

- PC

- PC-ISO (Bio-compatible)

- PC-ABS

- PPSF

- FDM Nylon 6 (Automotive)

- FDM Nylon 12 (Automotive)

- FDM Nylon 12CF (Aerospace and Automotive)

- (Carbon Fibre)

- ST-130

- Ultem 9085 resin (Aerospace)

- Ultem 1010 resin (Aerospace)

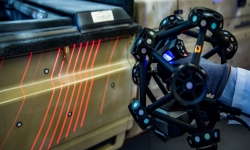

MetraScan 750 Optical Elite CMM scanner

The MetraScan scanner generates high-accuracy dimensional data regardless of part size, finish, material and complexity. It is therefore ideal for quality control, quality assurance, inspection and reverse- engineering applications.

The 3D scanning can be used for scan-to-print requirements. It can also be used to scan for verification and validation, as well as reverse engineering.