Focus areas

Mine digitalisation and automation

We use digital transformation tools such as digital twin simulations, data analytics, predictive modelling and integrated digital platforms to modernise and enhance the efficiency of the mining industry.

View more

Mine testing and training services

Our testing and training services are tailored to support the mining industry's zero-harm goal. Equipped with state-of-the art facilities, we deliver high-quality services in mechanical testing, emergency breathing equipment and mine fire and explosion safety. We support clients to reduce the risk of harm from equipment failures or catastrophic accidents.

View more

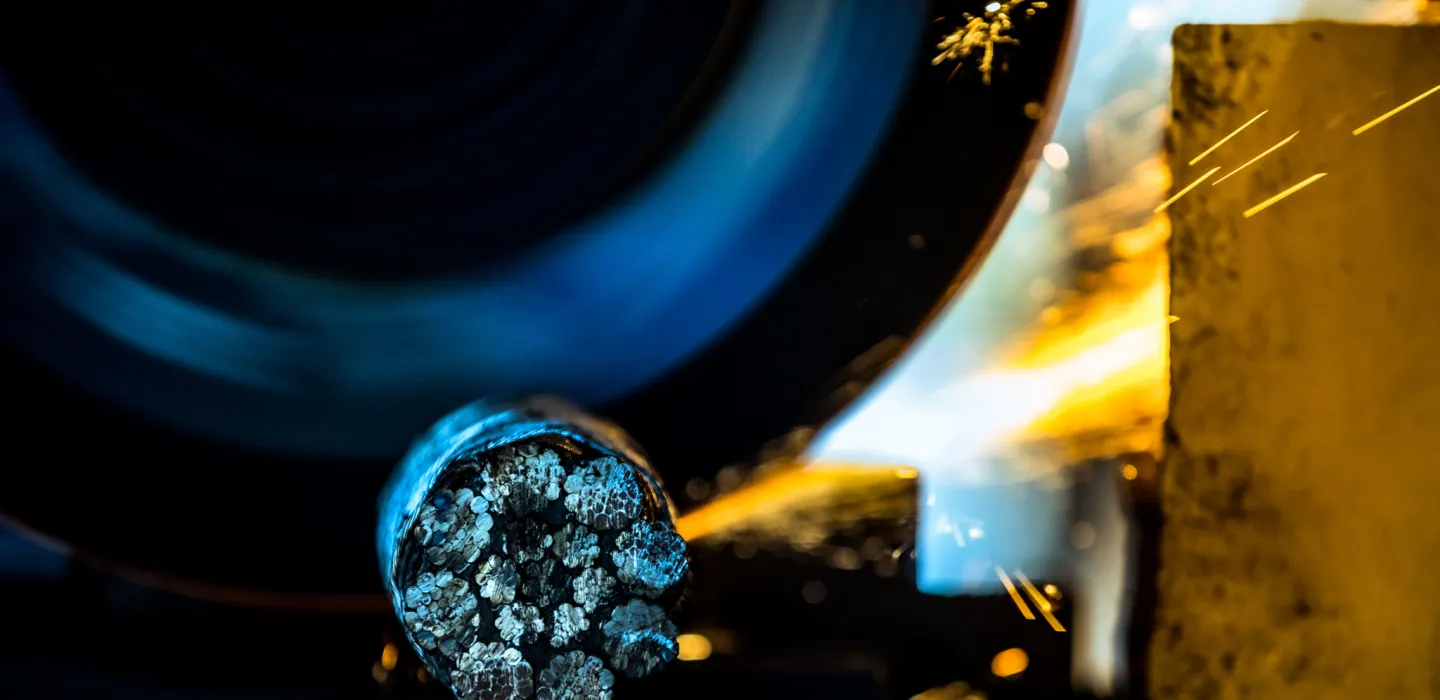

Mining extraction processes

We conduct field-based research, laboratory testing and advanced computational modelling to support and improve mining extraction processes. Our expertise includes rock behaviour, underground stability and resource optimisation, ensuring optimal mine productivity while upholding environmental responsibility and socially consciousness.

View more

Sustainable mining

We support mines in developing environmentally sustainable value chains to promote responsible mining practices and enhanced global competitiveness. Our services include mining environmental engineering, the promotion of a circular economy ecosystem and conducting decarbonisation assessments using simulations and digital twin technologies.

View more